Knowledge

what PDC bits should i use

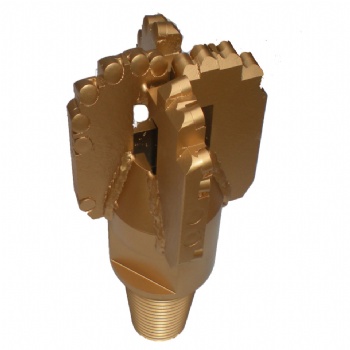

PDC BIT OPTIONS:

Body:

Steel body PDC bits are a lower cost alternative, to matrix body bits. They are generally preferred in soft formations, such as sandstone.

Matrix body PDC bits provide excellent resistance to wear. They are commonly used in harder more abrasive formations such as limestone and dolomite.

Number of Blades:

The number of blades on a PDC bit is largely determined by the formation being drilled.

Generally higher blade and cutter counts are used for harder formations, whereas in softer formations fewer blades can be used to increase ROP.

Gauge protections is applied to all bit blades to insure longevity and to sustain a straighter hole which increases ROP.

Cutter Characteristics (count and size):

Cutter count and size can be adjusted for drilling in specifi c formations. Small cutters and high cutter count are chosen for hard and abrasive rock formations,

whereas large cutters and a reduced cutter count are preferred for soft to medium formations.

Hydraulics:

PDC bits are available with flushing holes or open center and either fixed or adjustable nozzles.

Options are available for all varieties of PDC bits and are designed specific to those PDC bits to maximize bit performance and longevity

Categories

Contact Us

- +86-15036147531

- +86-13526863364

- info@chinapdcbit.com

- +86-13526863364